Production Process and Precautions of Butyl Rubber Stoppers

What is a rubber stoppers?

Rubber stoppers are ideal for stopperging joints or holes in laboratory glassware and forming liquid-tight seals.

Rubber stoppers are often used with glass containers such as test tubes, flasks, kettles and many other standard laboratory equipment.

We offer stoppers with and without pre-drilled holes in a variety of the most common sizes.

In fact, there are about 16 different sizes of standard laboratory rubber stoppers, but we have narrowed down the selection to only those that are suitable for commercial and hobbyist use.

What are the advantages of butyl rubber stoppers and the production process?

Butyl rubber stoppers are airtight, heat resistant, acid and alkali resistant, and have a high level of internal cleanliness. It quickly replaced natural rubber in the production of pharmaceutical stoppers. Butyl rubber is a synthetic rubber made of isobutylene and a small amount of isoprene (<3%) polymerized by ultra-low temperature (95℃), its unique chemical stability, excellent sealing properties ensure the quality of drugs, drug safety, while reducing the production of natural rubber stoppers required wax process, pad and tape fiber film process. Butyl rubber stoppers are far superior to natural rubber stoppers in terms of product specification, production level, application function and product quality.

Butyl rubber stopper intrinsic cleanliness, chemical stability, air tightness, biological function is very good, but due to the mixed formula and the added raw material concentration gradient contact, some molecules are highly active, drug encapsulation, drug absorption, adsorption, leaching, soaking, resulting in the problem of rubber stopper and drug compatibility. Therefore, the compatibility with the drug can be significantly improved by selecting an inert soft coating that covers the surface of the rubber stopper, blocking the direct contact between the drug and the rubber stopper. By forming a film on the outer surface of the butyl rubber stopper, the absorption, adsorption, leaching and permeation between the stopper and the drug can be effectively reduced and the long-term stability of the drug can be trekked; mechanical lubricity of the tracked rubber stopper.

The whole production process of butyl rubber stoppers mainly includes five parts: mixing of raw materials, sheet, vulcanization, rinsing and cleaning. The rubber mixing, vulcanization and cleaning are the most important parts of the whole production process. The quality control of these three processes determines the quality of the rubber stopper products.

Further reading:

10 Questions You Should Know About Stormwater Steel Reinforced PE Pipe

Top Benefits of Stormwater Steel Reinforced PE Pipe

Polyethylene vs. PVC: Which is Better for Your Project?

Key Questions to Ask When Choosing Polyethylene vs Polyvinyl Chloride

How to Choose the Right LPG Tube Safely?

10 Questions You Should Know About Solar Energy Solutions

10 Facts You Should Know about 100r3 Hose

In the process of rubber refining, high standard rubber raw materials, suitable fillers and strict process parameters should be used. If the butyl rubber stopper enterprises choose low standard rubber or mix with cheap common butyl rubber in order to reduce production cost, it will lead to the degradation of the anti-pull-out function of the finished rubber stopper, thus affecting its compatibility.

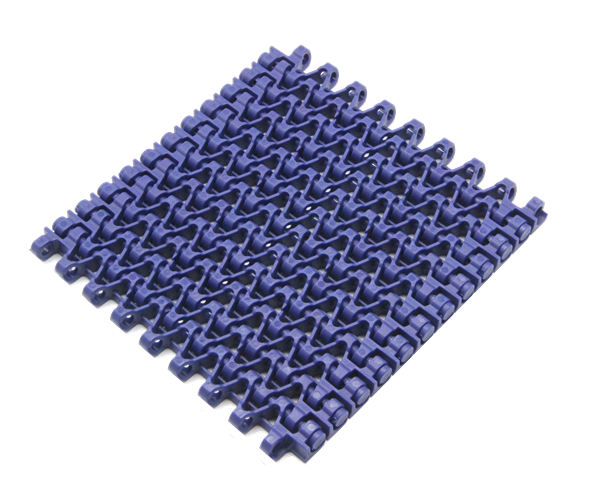

Perforated and non-perforated are available

In many cases, pre-drilled holes are useful.

For example, suppose you need to place a thermometer precisely in the center of a container while still maintaining an airtight seal. Having a pre-drilled hole in the center will ensure proper, consistent alignment.

Brinell funnels (for filtration) can also benefit from this type of stopper. If the holes are too small, they can easily be drilled larger so that they fit your own custom applications.

Not sure if your stopper needs holes? No worries! You can always use the Cork Drill to drill new holes to meet your specific needs.

Rubber stoppers are the most commonly used stoppers for laboratory applications and they are highly recommended for every lab.

Beware of leaks!

Please note that incorrect holes can also cause liquid chemicals to leak from containers if you are not careful, so make sure that all fittings (including the rubber stopper itself) fit snugly inside the container.

Always use the right size rubber stopper for your application -- if in doubt, don't force it!

Further reading:How Will En 857 1SC Shape Future Standards?

How to choose between polyethylene and PVC?

Understanding What UPVC Pipe Stands For: A Complete Guide

Are You Struggling with Hydraulic Hose Durability Issues?

Why choose Upvc Casing Pipes over alternatives?

Top 5 Tips for Efficiently Managing DIN EN 856 4SH Standards

How Can Wire Braided Steam Hoses Improve Your Hydraulic Efficiency?