Are polyurethane conveyor belts the optimal choice for your material handling needs?

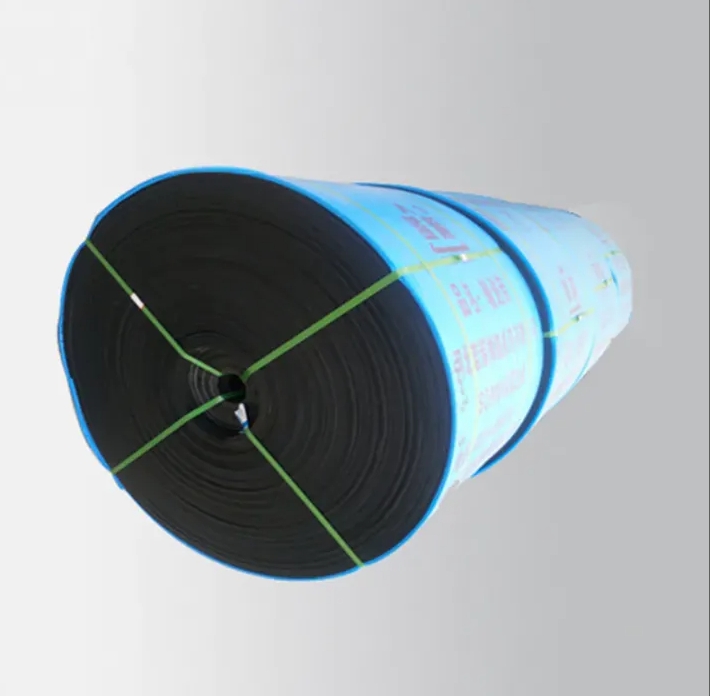

Polyurethane conveyor belts are a popular choice for material handling needs in various industries due to their durability, versatility, and resistance to wear and tear. However, determining whether a polyurethane conveyor belt is the optimal choice for your specific material handling needs requires consideration of several factors, such as the type of materials being handled, the environment in which the belt will operate, and the overall operational goals.

Polyurethane is a polymer that can be molded into various forms, including conveyor belts. These belts are typically made by coating a fabric or other core material with a layer of polyurethane, which creates a durable and flexible material that is resistant to abrasion, tearing, and chemical damage. Polyurethane conveyor belts are often used in applications that require high belt speeds, high load capacity, and/or resistance to harsh chemicals and other substances.

One of the primary benefits of using a polyurethane conveyor belt is its durability. Compared to other types of conveyor belts, polyurethane belts have a longer service life and require less maintenance. This means that they can be more cost-effective in the long run, especially in high-volume operations. Additionally, polyurethane belts are resistant to oil, grease, and other chemicals, which can make them an ideal choice for applications in which these substances are present.

Different Styles and Designs of Euro Head Caps

How Do I Choose The Proper Plastic Materials?

Choosing the Right Drainage Pipe: Factors to Consider

What is dredge pipe used for?

How can I ensure the recycled PET flakes I purchase meet industry standards and regulations?

Extruded PTFE Tubing: The Ultimate Guide for High-Performance Applications

Maintaining Clean and Hygienic Environments with Disposable PE Shoe Covers

Another advantage of using polyurethane conveyor belts is their versatility. Polyurethane can be molded into different shapes and sizes, which means that polyurethane belts can be customized to fit specific material handling needs. Polyurethane belts can be manufactured with different textures and profiles, which can help to prevent slippage and improve the grip of the belt. This makes them an excellent choice for applications that require precise positioning of the material being handled.

However, polyurethane conveyor belts may not be the optimal choice for every material handling application. For example, if the material being handled is abrasive or has sharp edges, a polyurethane belt may not be the best option, as it could wear down or become damaged more quickly than other materials. Additionally, if the environment in which the belt will operate is extremely hot or cold, a polyurethane belt may not be the best choice, as extreme temperatures can affect the material properties of the belt.

In conclusion, determining whether a polyurethane conveyor belt is the optimal choice for your material handling needs requires careful consideration of various factors. While polyurethane belts have many advantages, such as durability and versatility, they may not be the best choice for every application. By taking the time to evaluate your specific material handling needs and considering the pros and cons of different types of conveyor belts, you can select the best option for your operation

Further reading:Advantages of Silicone Sealing Valves

Key Considerations When Choosing Rubber Stoppers

What is the difference between MDPE and HDPE gas pipe?

What Material Is Used for High-Pressure Seals?

RPET: Transforming Plastic Waste into Sustainable Solutions

Why Can't Natural Rubber Be Used to Make Products?

RPET Material – 10 Frequently Asked Questions